| Availability: | |

|---|---|

| Quantity: | |

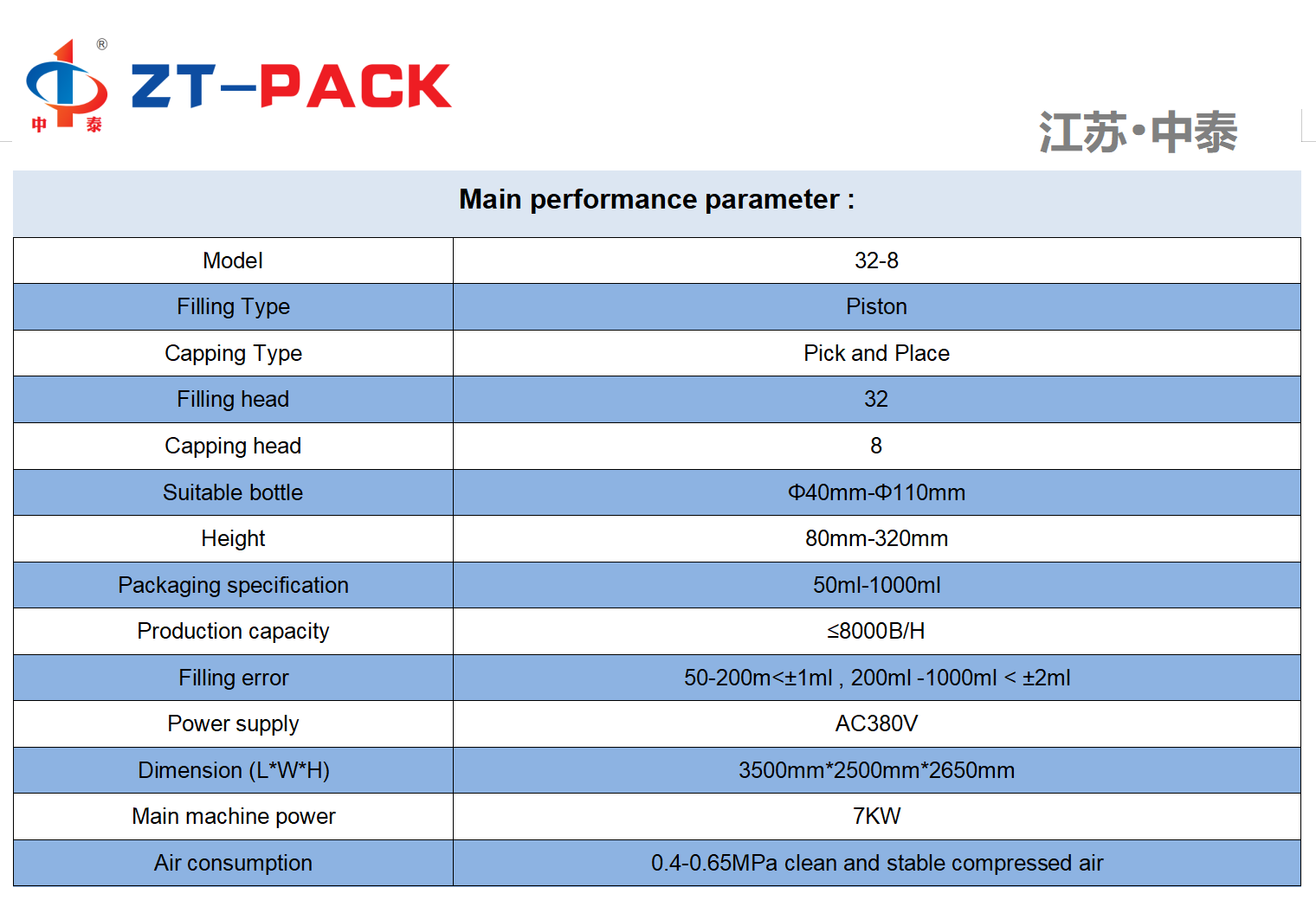

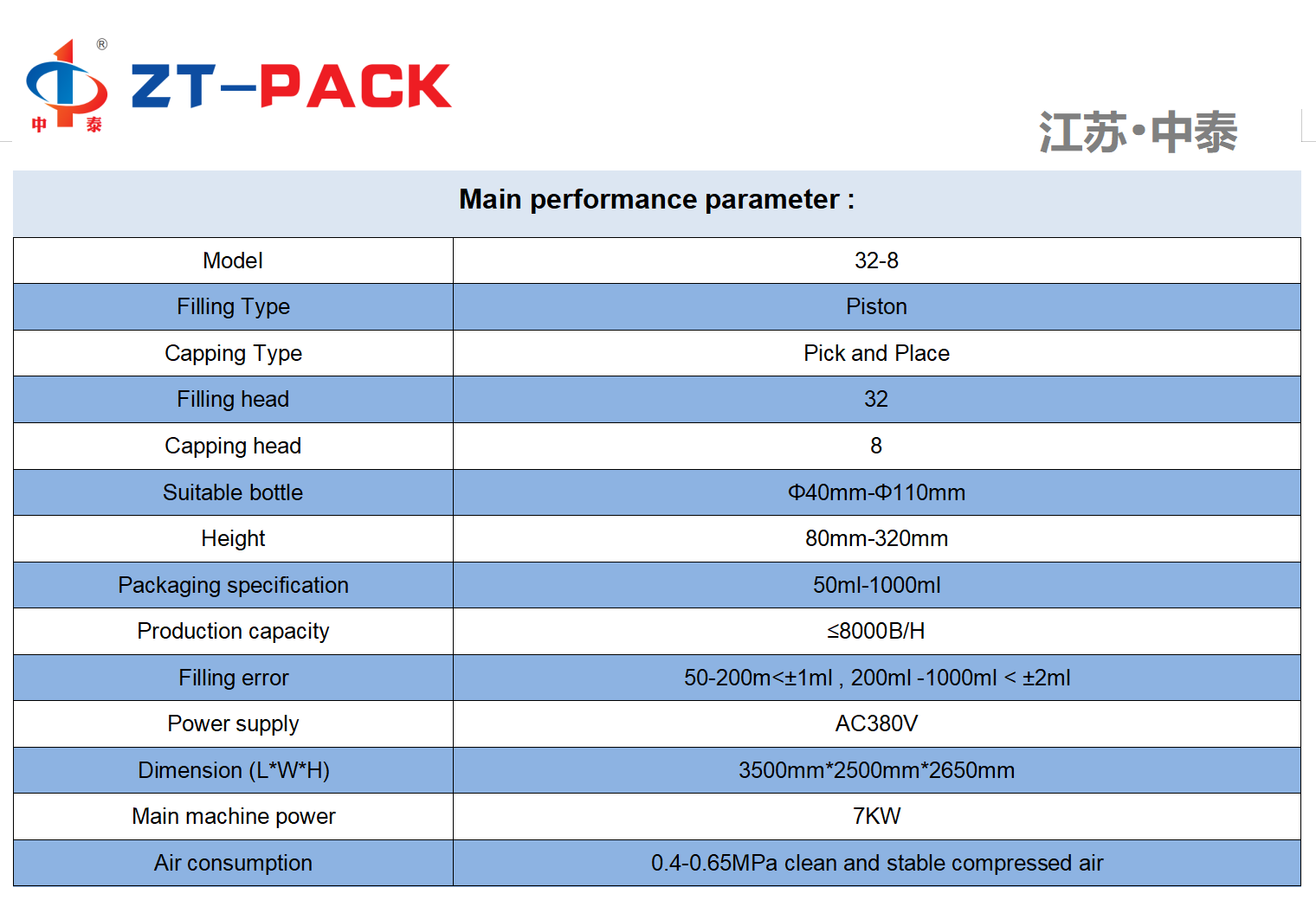

32-8

ZT-PACK

Machine Name : 7000-8000BPH Rotary MonoBlock Piston Filling Capping Machine

Type: 32-8

Suitable For Filling: Ketchup / tomato paste /Salad Dressing /sauce /Jam ...viscous foods ...Etc kinds Products

Filling Range : 100ml-1000ml

Filling System : Piston

Capacity Speed : 7000-8000BPH

Accuracy : 0.5%

Bottles Material : Plastic & Glass / Round & Flat

Suitable for Ketchup Sauce food packing , with bearing for hot filling system

Product description:

This is our traditional 2 in 1 machine, apply to 100~1000 ml round and irregular bottles. The advantage of this machine is compact design, easy operation, simple maintenace, accessories have long service life. Working stable and high accuracy, the outer frame are all high quality stainless steel, meet GMP standard.

With 32 filling nozzles +8 capping heads

1、 Rotary piston filling and capping machine is new-generation quantitative filler.

2、This machine is suitable for foodstuff, medicinal, cosmetic, chemical industry and pesticide industry.

3、Filling part controlled by PLC and touch screen, adopt piston to filling.

4、Capping part with inlet bottle, sorting cap, feeder cap, capping and outlet bottle.

5 .Dispatch cap in high speed. Bottle and cap synchronous operation. With supermatic productivity and high automation, the rotary piston machine is new-generation quantitative filler.

This machine is an integration of mechanics and electrics. It is automatically controlled by PLC and touch screen controlled panel. It is an ideal model which integrates mechanical, electrical, light and gas.

Suitable for Fill :

Details pictures :

Machine Name : 7000-8000BPH Rotary MonoBlock Piston Filling Capping Machine

Type: 32-8

Suitable For Filling: Ketchup / tomato paste /Salad Dressing /sauce /Jam ...viscous foods ...Etc kinds Products

Filling Range : 100ml-1000ml

Filling System : Piston

Capacity Speed : 7000-8000BPH

Accuracy : 0.5%

Bottles Material : Plastic & Glass / Round & Flat

Suitable for Ketchup Sauce food packing , with bearing for hot filling system

Product description:

This is our traditional 2 in 1 machine, apply to 100~1000 ml round and irregular bottles. The advantage of this machine is compact design, easy operation, simple maintenace, accessories have long service life. Working stable and high accuracy, the outer frame are all high quality stainless steel, meet GMP standard.

With 32 filling nozzles +8 capping heads

1、 Rotary piston filling and capping machine is new-generation quantitative filler.

2、This machine is suitable for foodstuff, medicinal, cosmetic, chemical industry and pesticide industry.

3、Filling part controlled by PLC and touch screen, adopt piston to filling.

4、Capping part with inlet bottle, sorting cap, feeder cap, capping and outlet bottle.

5 .Dispatch cap in high speed. Bottle and cap synchronous operation. With supermatic productivity and high automation, the rotary piston machine is new-generation quantitative filler.

This machine is an integration of mechanics and electrics. It is automatically controlled by PLC and touch screen controlled panel. It is an ideal model which integrates mechanical, electrical, light and gas.

Suitable for Fill :

Details pictures :

Overseas exbihition

Have an excellent after-sales service team to ensure that the first time to solve customer after-sales problems.

According to customer needs, tailor-made packaging lines.

Our aim is to recommend the right machine to customers, not to recommend expensive machines.

The product has one year's guarantee with it from the day of being tested and qualified. In the guarantee period, the product's damage is not man-made, free repair.

Maintenance service:

Expertise in type

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : fiona@ztpack.net 395377419@qq.com