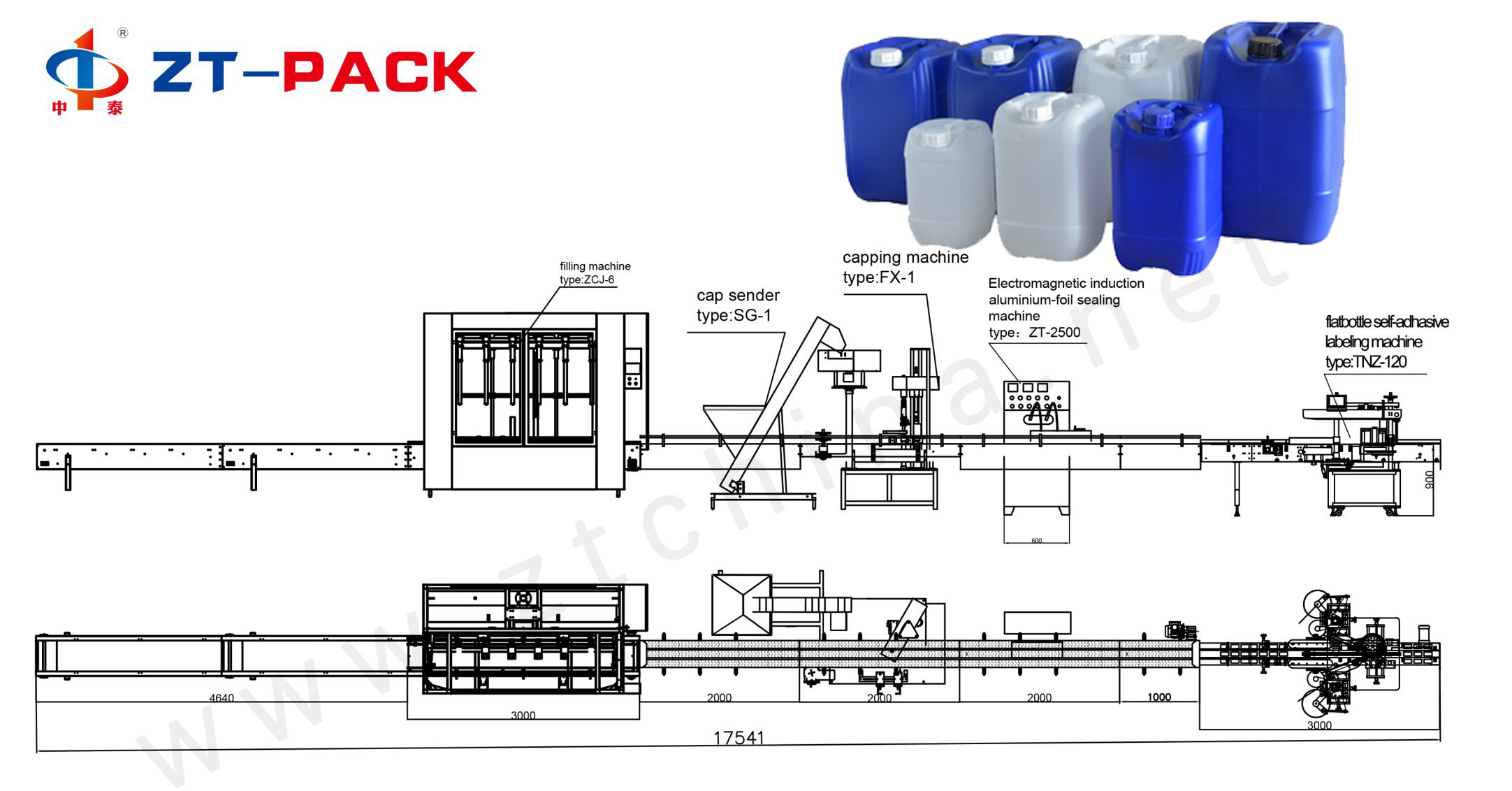

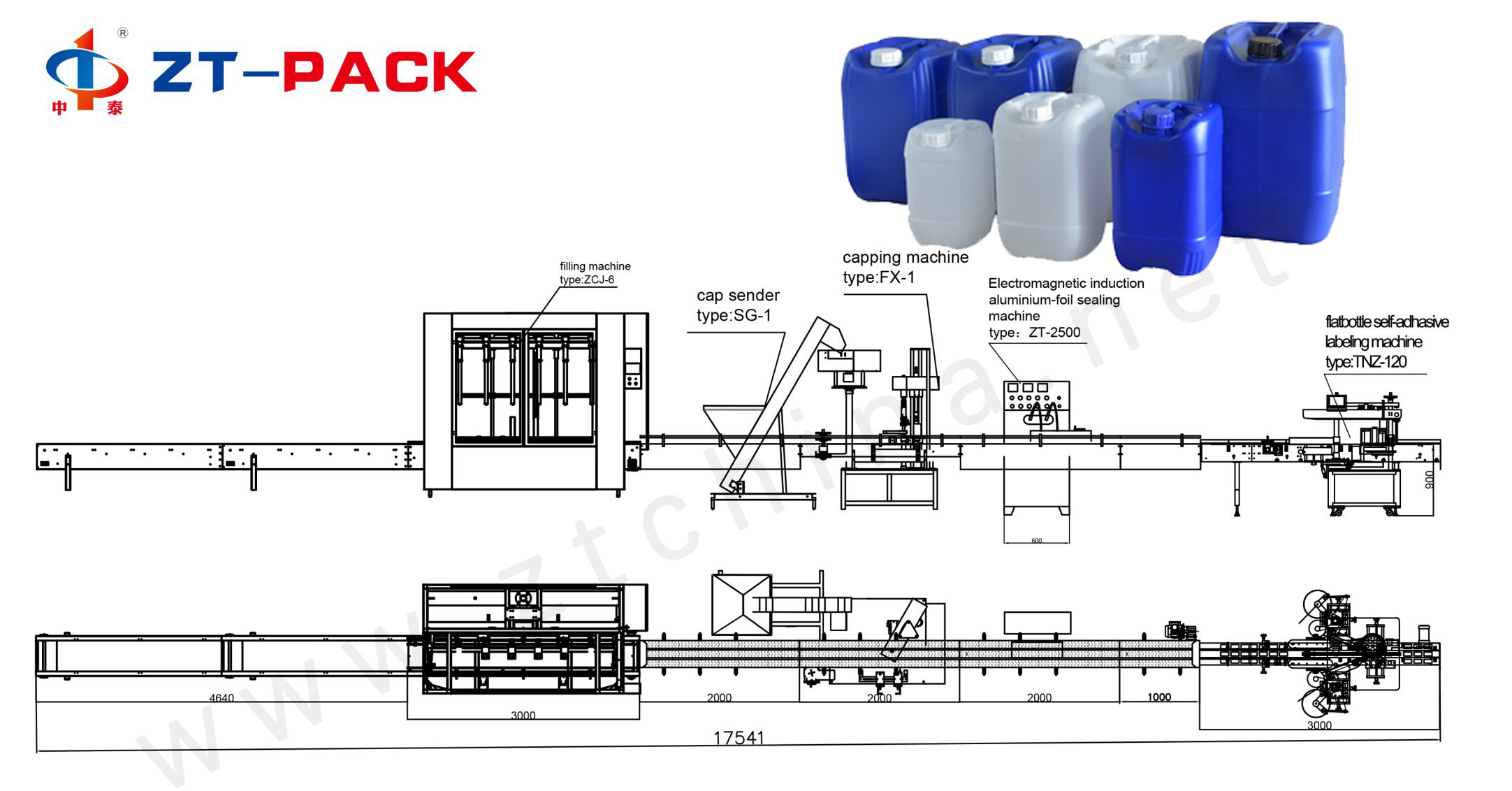

ZT Packaging Machinery is a professional manufacturer with more than 20 years experience on filling and packaging production ines. We have fully automatic paint filling machine, food filling machine, shampoo bottle filling machine and so on. Aggressive price with top quality and satisfying support make us earned extra customers.

So we want to avail ourselves of opportunity establishing business relation with you. We wish to work along with you and request common enhancement. Our company always concentrate on the development of the international market, we have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

If you have any requests or want to know more information about filling machine and packaging production ines, please contact us zt-pack@hotmail.com and we will reply you within 2 hours.

LP-200 Automatic bottle unscrambler machine is a high-tech automatic bottle sorter for food and beverage industry. The b

Plastic bottle unscrambler is often used for the plastic round bottle finishing machine, it is an automatic filling mach

Since our beginnings, we've designed our packaging and bottling equipment to meet the needs of our customers. Our fillin

As far as we know, there are many kinds of it, and today this article will introduce you to all kinds of it. If you are

An introduction to shampoo filling machineShampoo filling machine is a new type of electronic filling machine that can f

How to choose sauce filling machineThe sauce filling machine is developed based on the advanced filling machine technolo

Automatic bottle unscrambler machine is making up of bottle elevator , round plate, bottle-reject, bottle-arranging part

A brief introduction to hand sanitizer filling machineHand sanitizer filling machine is a kind of washing filling machin

Automatic bottle capping machine has a unique purpose, and has a very good sealing effect. It is a mechanical equipment

Disinfectant filling machine may be a reasonably laundry filling machine, that is a sophisticated filling machine for fi

4. It applies dive method to fill and it reduces foam. This lube oil filling machine is for filling 20kg to 30kg liquid. It automati

It is also possible to combine 2 capping turrets on the same machine, with different possible combinations, such as: Screwcap and wine cork Wine cork and crown seal Screwcap and T cork

China Piston Jam Filling Machine, Find details about China Jam Filling Machine, Filling Machine from Piston Jam Filling Machine

Automate your production with a price canned tomato paste filling machine from . Browse through filling machines and choose the machine your business needs.

Vast range of solutions for large size containers: PET is becoming the most flexible and cost effective material for the manufacture of large size containers. 5 to 10 litre PET containers for edible oil are standard in the market. Nowadays,

The presence of a pharmaceutical packaging unscrambler is essential in a production line. This machine is necessary for the packaging of the products and is usually located at the last stage of the production process. Whether it is for primary or secondary packaging, the quality of the product packaging remains high with this type of machine.

The main target of an aseptic filling line is to reach and to maintain the sterility of container, environment and product through each step of the bottling process. In this way, the organoleptic features of the product are kept for a pre-determined shelf life at room temperature. This target should ideally be reached at the lowest capital and ...

Quality 10 ml liquid soap filling machine price

Honey Processing Machine Pioneers in the industry, we offer honey processing plant with moisture reduction unit, honey processing plant, small scale honey processing machine, small honey filling machine, natural orignal taste honey

The Semi Automatic Pouch Filling Machine from the Unique packaging Systems are a machine of great technical prowess and international repute. Our assortment also includes a lot many customization offers that make our