ZT Packaging Machinery has got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, top quality handle systems along with a friendly expert gross sales group pre/after-sales support.

We offer jar labeling machine, Cooking Oil Filler machina, Detergent Filling Machine and We believe that our warm and professional service will bring you pleasant surprises as well as fortune.

During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Cap machine is a kind of machine which can seal the product with the form of bottle cap. The cap achieved by using this

Automatic capping machine is based on the principle of electromagnetic induction. The aluminum foil on the bottle mouth

Capping machine refers to the machine that seals the instrumentation once the merchandise is crammed within the packagin

Important information about gel filling machine ZT-pack specially designed and manufactured a filling rotary valve for c

Disinfectant filling machine may be a reasonably laundry filling machine, that is a sophisticated filling machine for fi

Liquid soap is one of the thicker liquids and requires machines that can handle it effectively. So the liquid soap filli

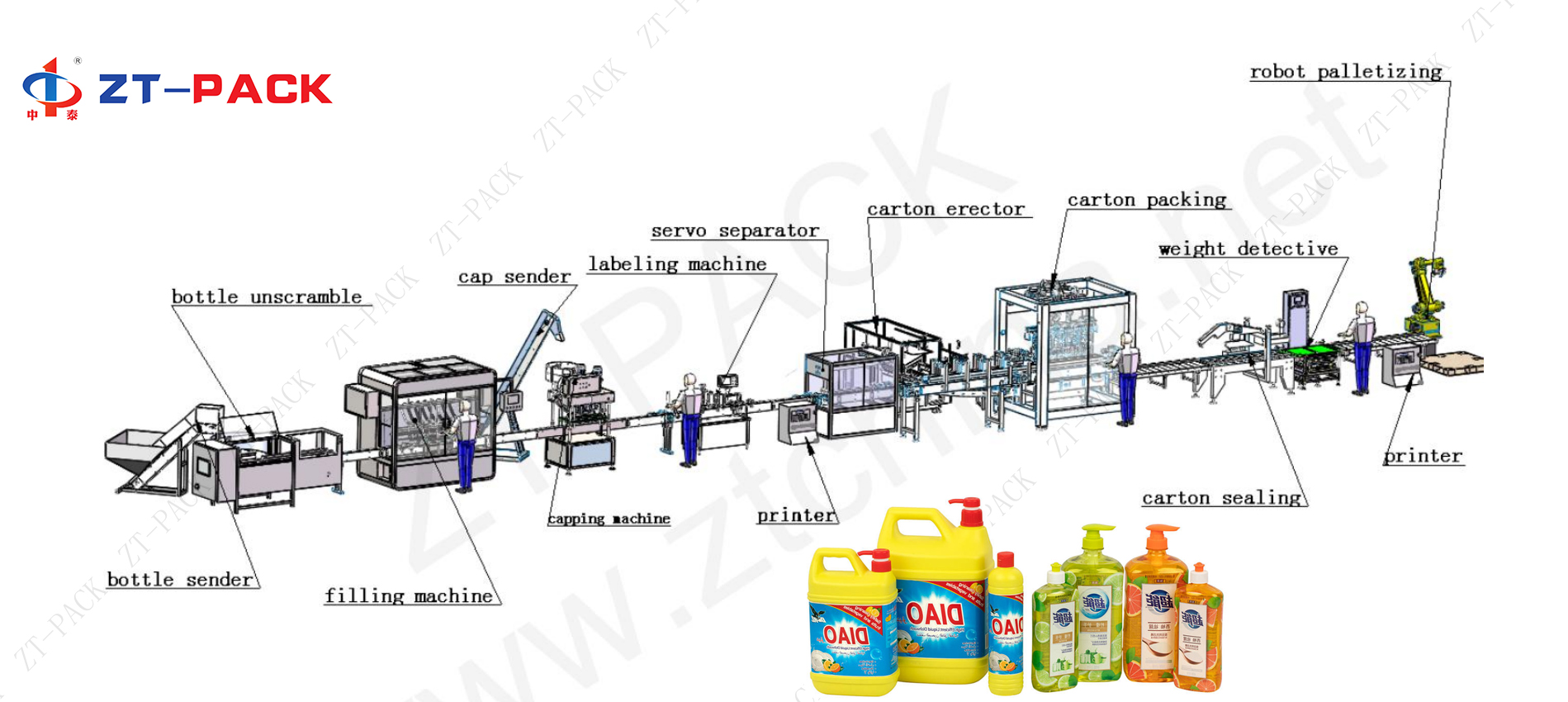

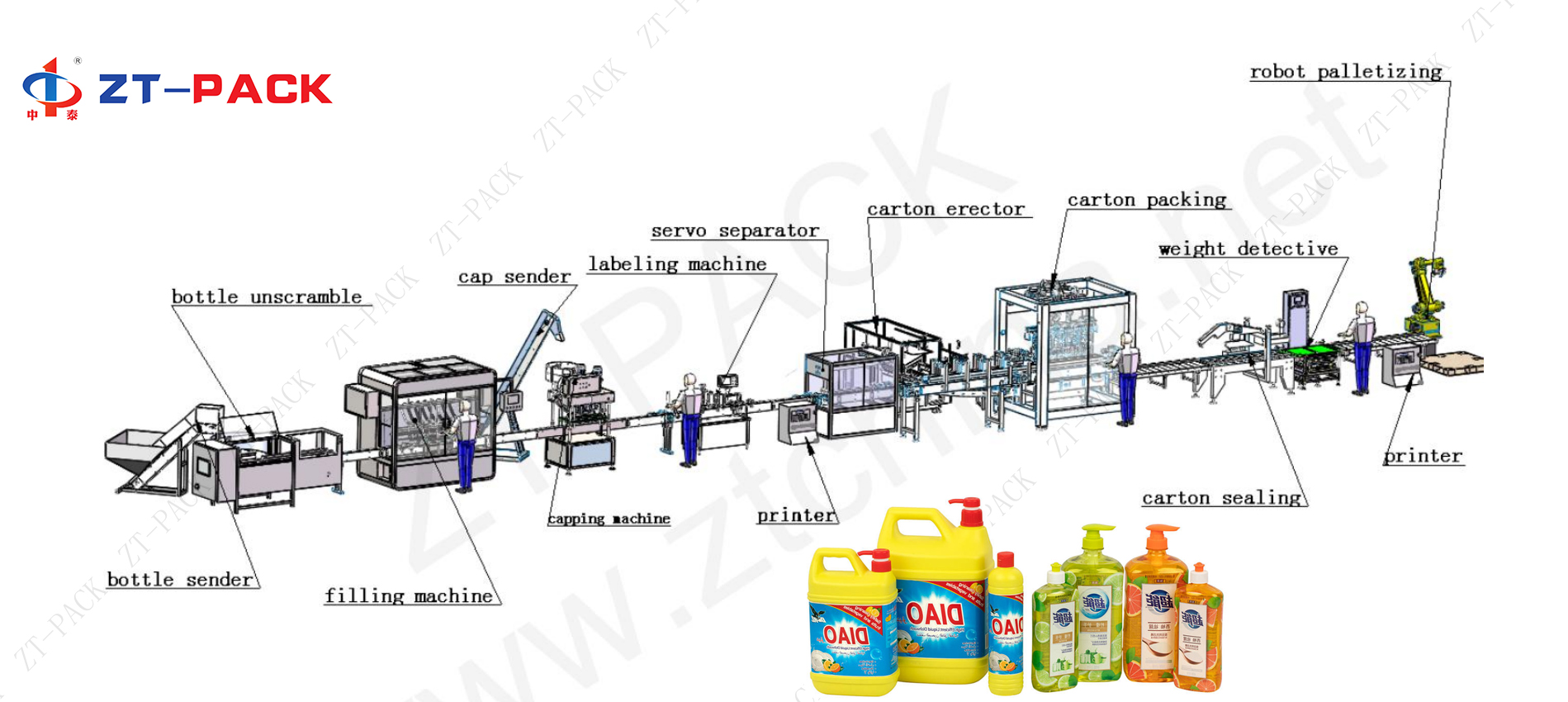

The carton package machine is the most common and important package of our company. Carton package machine can be used t

LP-200 Automatic bottle unscrambler machine is a high-tech automatic bottle sorter for food and beverage industry. The b

Capping machine refers to the machine that seals the instrumentation once the merchandise is crammed within the packagin

How to choose sauce filling machineThe sauce filling machine is developed based on the advanced filling machine technolo

It adds more delicacies to the food and makes people enjoy the feast on the tip of their tongue. Ketchup is an important

Carton package machine is a new and advanced pneumatic packaging machine of baler. Mainly used in carton enterprises and

A brief introduction to hand sanitizer filling machineHand sanitizer filling machine is a kind of washing filling machin

Top quality china automatic machines to make plastic bottles/bottle blowing machinery/Pet Bottles Blowing Machine 750ml; ... This Vegetable Oil Filling Machine contains filling and capping two

View more. Automatic Tube Filling and Sealing Machine (Ultrasonic tube sealer, PLC system and touch screen controller) Filling Machine. Sealing.

Alcoholic Beverage Filling and Packaging Systems. The goal is to deliver a properly labeled amount of adult beverage to the consumer in an attractive container that promotes your offering over the competition. Accutek has been providing customers with superb filling machines for thirty years. At Accutek, we know the ins and outs of the liquid ...

Supply Ability: 20 Set/Sets per Month: Delivery Time: Deliver goods within 15 working days after receiving 70% final payment: Packaging Details: Exporting long distance Wooden Case: Name: Full automatic jam filling capping machine shanghai paixie: Packing Details: capping machine: Dimension(L*W*H): 2200*88589*1200mm: Voltage: 220V/50HZ: Power ...

Glass Jar Labeling Machine Manufacturers, Factory, Suppliers From China, We are sincerely looking forward to cooperate with buyers all around the world. We imagine we will satisfy you. We also warmly welcome shoppers to visit our organization and purchase our merchandise. (086)769-81886391. amanda@finecolabeler.

Setting the bar in manufacturing speed, product breadth, and quality. Our High-Speed Liquid Filling Lines deliver best-in-class service, innovative packaging solutions, and streamlined sourcing. With a focus on the automotive and industrial markets, our expert sourcing capabilities offer a range of packaging options for oils, lubricants, fluid ...

Comparing pet bottle unscrambler prices. You can easily wholesale quality pet bottle unscrambler at wholesale prices on .

The automatic liquid filling equipment can adopt multiple filling heads/nozzles to ensure high efficiency. For example, the speed of the 12-head liquid filling machine can reach 3000 bottles/hour. The adjustable filling speed can meet your different demands. And the height-adjustable nozzles are suitable for different types of bottles.

Filling Machine, Bottling Machine, Beverage Filling Machine manufacturer / supplier in China, offering Automatic PLC Controlled Round Square Oval Rectangular Pet Bottle Liquid /Oil / Water / Drinks/ Filling Bottling Machinery Production Line, Automatic 2 in 1 Edible /Cooking /Olive/Food Oil Pet /Glass Bottle Filling/Bottling/Packing Machine, Liner Type Fully Automatic Pet