ZT Packaging Machinery abides by the contract, conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner.

We are professional filling machine supplier includes Edible Oil Filling Machine, Lubricant Oil Filling Machine, Chemical Filling Machine, Agrochemicals Drum Filling Machine, sauce bottle filling machine and so on. With a wide range, good quality, reasonable prices and good service, we will be your best business partner.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We've got won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

Bleach is a mixture of sodium hypochlorite and sodium chloride produced by the reaction of chlorine gas and sodium hydro

With the development of economy and the improvement of people's living standard, every commodity in circulation needs to

The carton package machine is the most common and important package of our company. Carton package machine can be used t

Advantages and unique technology of disinfectant filling machine Disinfectant filling machine is my company developed a

Bottle unscrambler machine disperses the plastic bottles in a messy situation and regularly arranges the bottles on the

How to clean liquid detergent filling machine properly? Liquid detergent filling machine is an extremely flexible fillin

Summary description)1.Service of guaranteeing to keep the product: the product has one year's guarantee with it from the

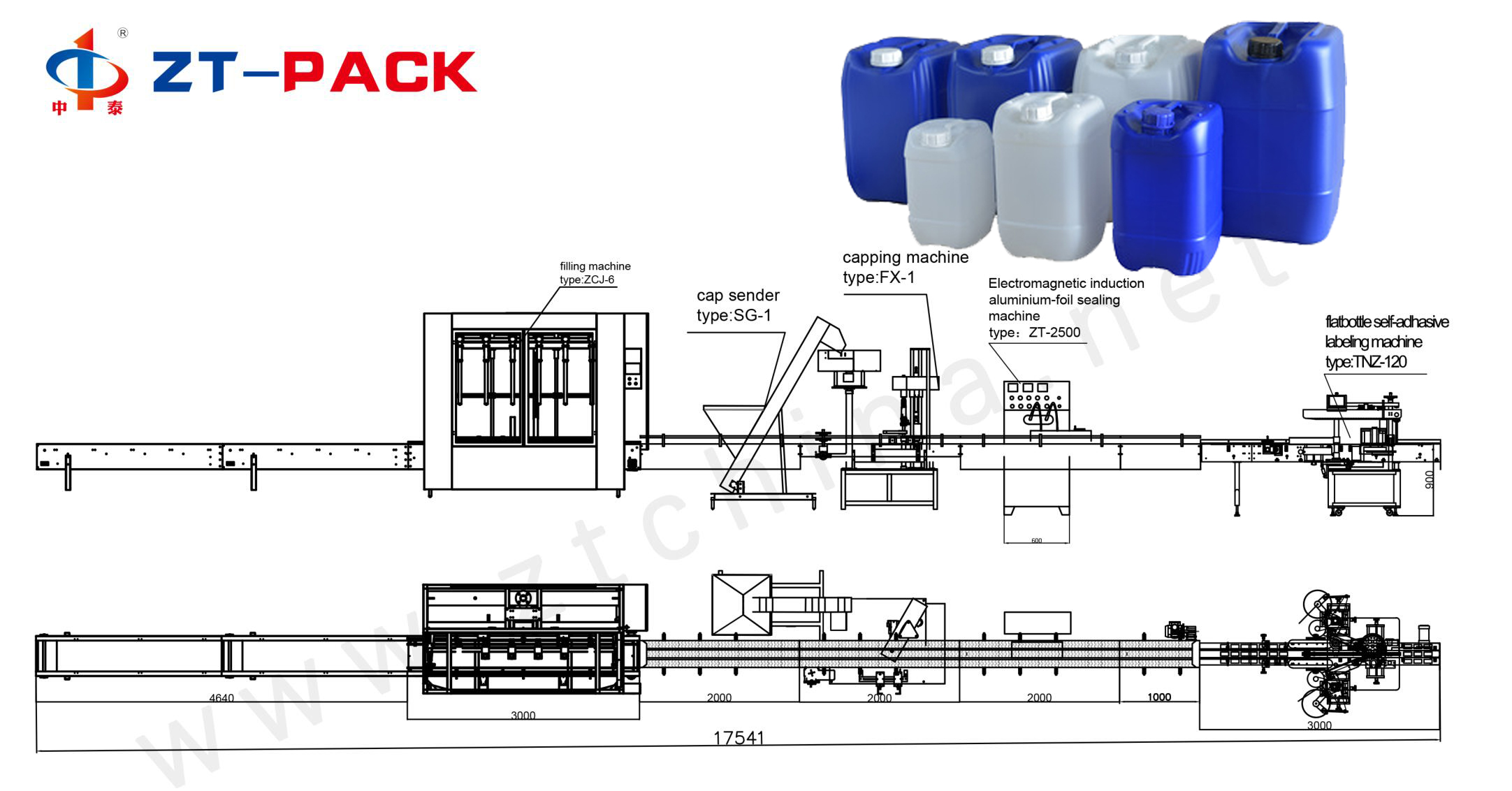

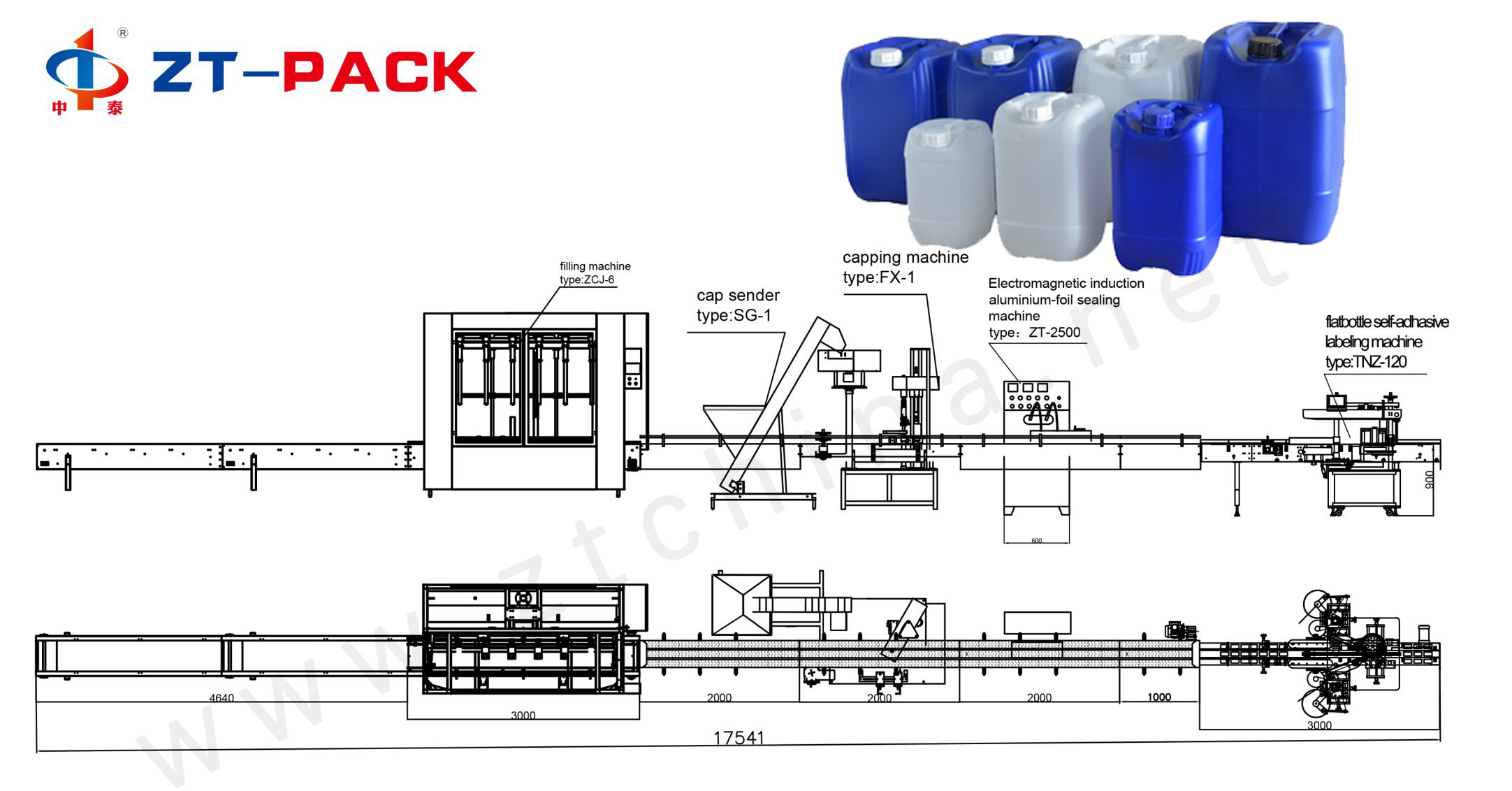

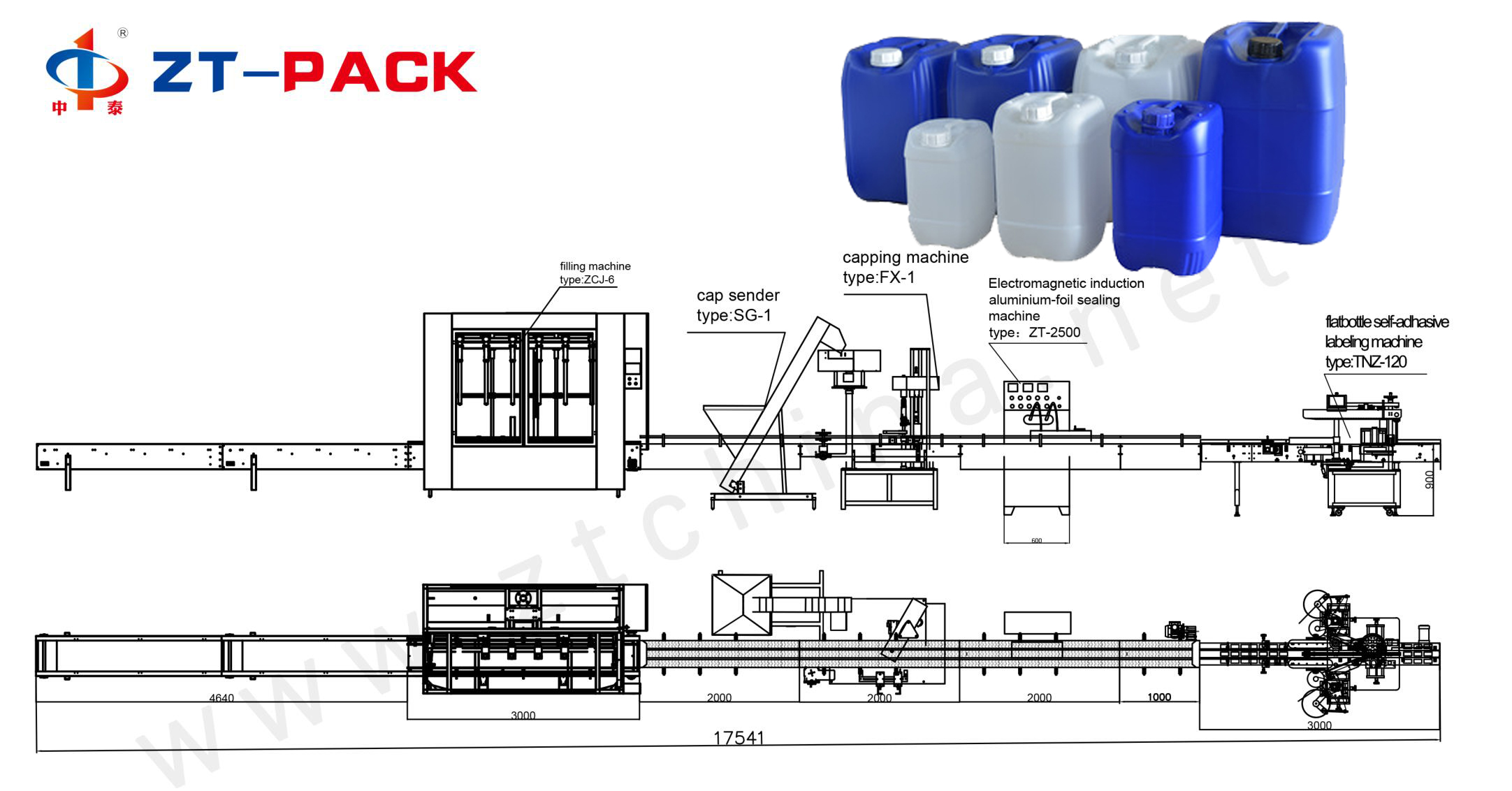

In order to fulfill the mechanized production of products, several production enterprises began to adopt a totally autom

Capping machine may be a machine that seals the containers stuffed with product. Once the product are placed into the pa

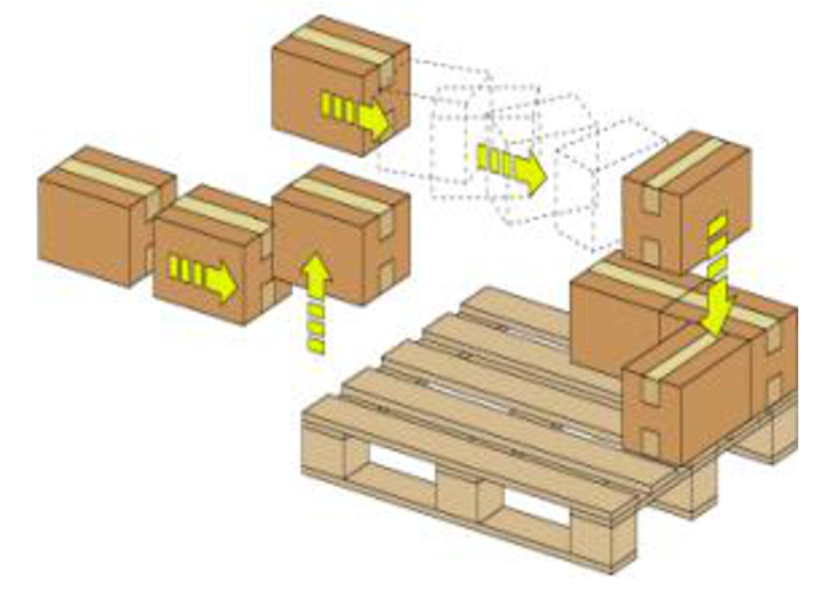

The palletilizer machine adopts automatic logistics storage equipment to realize the automatic management of three-dimen

DFF6 2 heads pneumatic paste gel and hand sanitizer filling machine, alcohol filling machine. Free shipping by express ( Delivery time 5~15 days) Please email us for more details! ...

Description. Lineal Unscrambler for empty plastic bottles with no compressed air consumption, with the consequent energy savings. The Unscrambler has a 1000li feeding hopper to discharge the bottles to the main body of the Unscrambler. Continuously in 2 phases the bottles are placed in vertical position on the exit conveyor of the PL Unscrambler.

Get Price Quote. Weight : 100-500kg, 1000-2000kg, 2000-4000kg, 500-1000kg Automatic Grade : Automatic Power : 1-3kw, 3-5kw, 7-9kw, 9-12kw Condition : New Driven Type : Elecric Warrenty : 5years We are the ultimate destination to avail efficiently working Syrup Filling Machine . The Syrup Filling Machine offered by us is fabricated using latest technology as well as superior

Newest Design BSC-A03 Series 5~50ml Manual Liquid Filling Machine For Filling of liquid, liquid food, oil, shampoo, shampoo cream liquid substance,with paste liquid filling. . Using the back sealing form, make the bag more beautiful. Contact Us Send Inquiry.

NEW. Manufacturer: Proman. High Efficiency Hand Washing Liquid Shower Gel Linear Bottle Filling Machine The filling machine s are closely linked in daily life, driving the cost and production efficiency of daily chemical products such as wa...

Liquid/Paste Filling Machine Manufacturers, Factory, Suppliers From China, Leading the trend of this field is our persistent objective. Supplying first class solutions is our intention. To create a beautiful upcoming, we wish to cooperate with all close friends in the home and overseas. Should you have got any interest in our products and solutions, remember to never wait to

Sleeve Labeling Machine Shrink Sleeve Labeler. Shrink Labeler Bottle Sleeve Machine (Speed 1000-12000BPH) Bottle Shrink Sleeve Machine Shrink Label Machine (Speed 40 Meter Per Min) Shrink Sleeve Labeler Bottle Label Shrink Machine (45 Meter/Min) Sleeve shrinking tunnel with steam generator. Total 1 Page 4 Records.

Pacific rotary flow meter fillers for foods and beverages are offered in filler only, monobloc filler-capper, and tri-bloc rinse-fill-cap configurations. They are designed and built for hygienic product environments and stainless steel construction with NEMA 4X electrical enclosures are standard. Specialized models including explosion-proof ...

We find 597 products about bottle unscrambler machine from 88 manufacturers

Glass Bottle Beer Filling Machine for sale, Quality Fully Automatic Alcohol Filling Machine For Beer/Wine/Vodka Making on sale of Zhangjiagang Longway Machinery factory from China. ... 100% reliable suppliers from China. And this service is free of charge. we have buyer assistants who speak English, French, Spanish.....and we are ready to help ...